Txhob lo lo ntxhuav Ci ntsa iab Xim Ceev Gradient Hloov Zaj sawv Multicolored 3D Tshuab Luam Ntawv PLA Filament

Cov yam ntxwv ntawm cov khoom

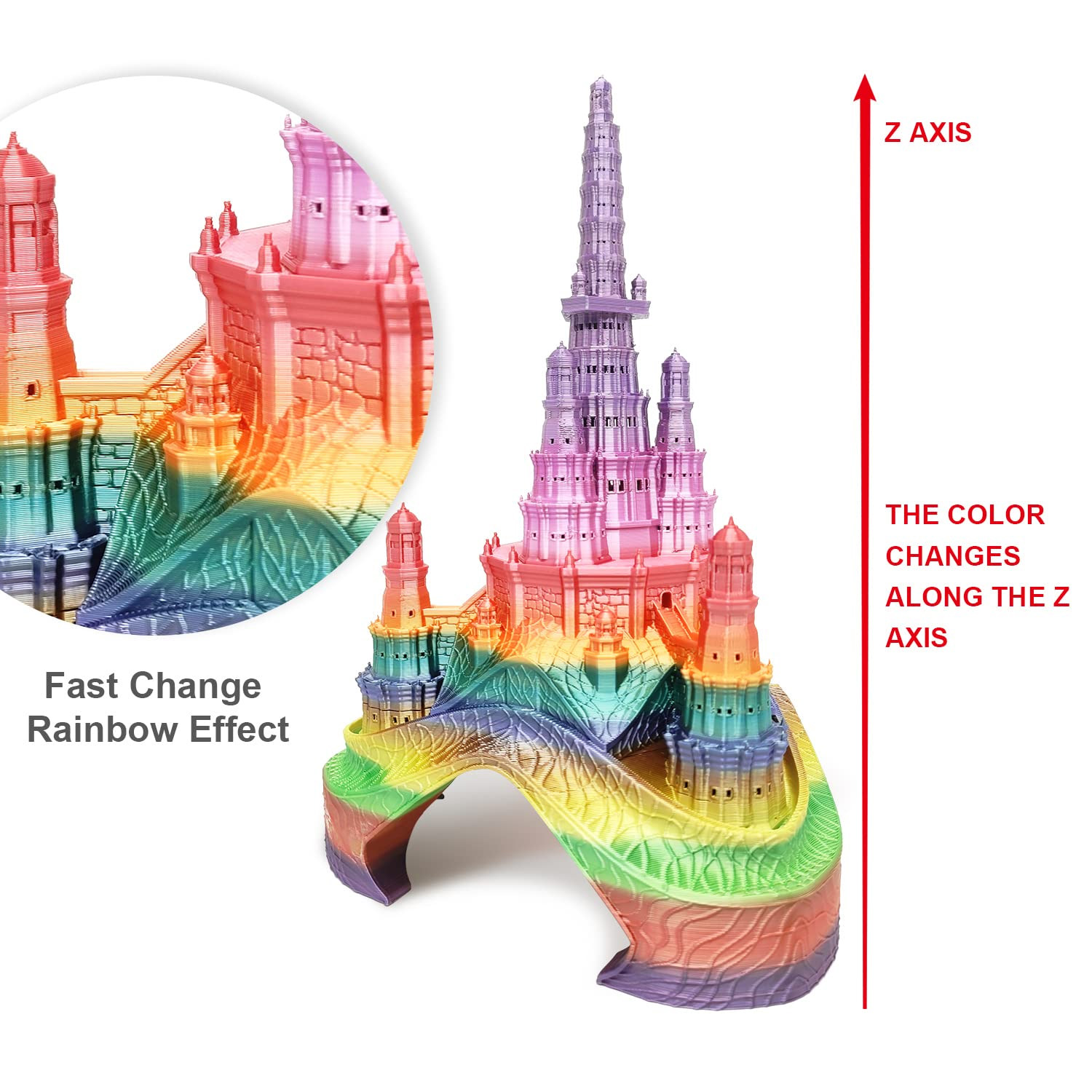

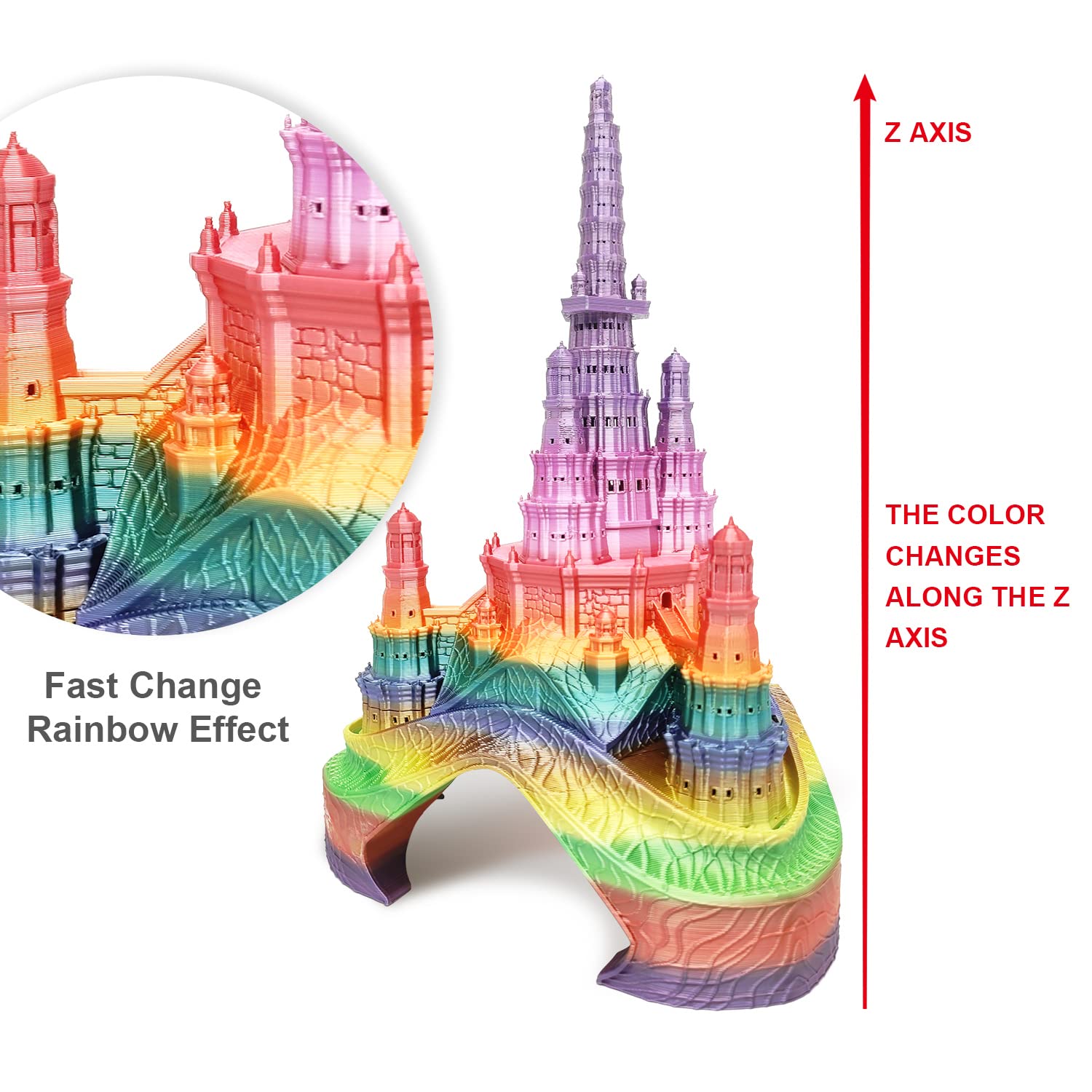

Qhov tshwj xeeb ntawm Torwell rainbow multicolor silk PLA filament yog nws cov xim zaj sawv. Cov khoom siv no yog ua los ntawm kev sib xyaw ntawm PLA thiab lwm yam khoom, uas tsim cov xim sib txawv ntawm cov khoom luam tawm, ua rau nws zoo tagnrho rau kev ua cov duab kos duab thiab cov khoom dai kom zoo nkauj. Tsis tas li ntawd, Torwell rainbow multicolor silk PLA filament muaj cov khoom siv kho tshuab zoo heev thiab qhov chaw ci ntsa iab, ua kom ntseeg tau tias siv tau zoo thiab siv tau ntev ntawm cov khoom luam tawm.

| Hom | Torwell |

| Khoom siv | Cov khoom sib xyaw ua ke ntawm cov polymer Pearlescent PLA (NatureWorks 4032D)) |

| Txoj kab uas hla | 1.75mm/2.85mm/3.0mm |

| Qhov hnyav tag nrho | 1 Kg/lub raj; 250g/lub raj; 500g/lub raj; 3kg/lub raj; 5kg/lub raj; 10kg/lub raj |

| Qhov hnyav tag nrho | 1.2Kg/lub voj |

| Kev kam rau siab | ± 0.03 hli |

| Ntev | 1.75 hli (1 kg) = 325 m |

| Chaw Khaws Khoom | Qhuav thiab cua nkag tau |

| Qhov Chaw Ziab Khaub Ncaws | 55˚C rau 6 teev |

| Cov ntaub ntawv txhawb nqa | Thov nrog Torwell HIPS, Torwell PVA |

| Kev Pom Zoo Txog Daim Ntawv Pov Thawj | CE, MSDS, Reach, FDA, TUV thiab SGS |

| Sib xws nrog | Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker thiab lwm yam FDM 3D printers |

Qauv Qhia

Cov Xim Tshwj Xeeb Uas Muaj Xim Hlau Uas Muaj Xim Sib Txawv:

Nws yog Gradient Xim, Nyob ib ncig ntawm txhua 3 - 5 Meters Hloov Xim, Nws yog Random hloov ntawm Ib Xim mus rau Lwm; Nws yog Amazing rau Luam Ntau Yam Xim Tshwj Xeeb hauv Ib Lub Spool Filament uas txhawb nqa Koj Txoj Kev Tsim Kho Tshiab thiab Tsim Qauv hauv 3D Printing World Zoo heev!

Cov Ntawv Pov Thawj:

ROHS; REACH; SGS; MSDS; TUV

| Qhov Ceev | 1.21 g/cm33 |

| Cov Ntsuas Kev Nqus Qhuav (g / 10 feeb) | 4.7(190℃/2.16kg) |

| Kub Distortion Temp | 52℃, 0.45MPa |

| Lub zog tensile | 72 MPa |

| Kev ntev thaum tawg | 14.5% |

| Lub zog flexural | 65 MPa |

| Flexural Modulus | 1520 MPa |

| Lub zog cuam tshuam IZOD | 5.8kJ/㎡ |

| Kev ruaj khov | 4/10 |

| Kev luam tawm tau | 9/10 |

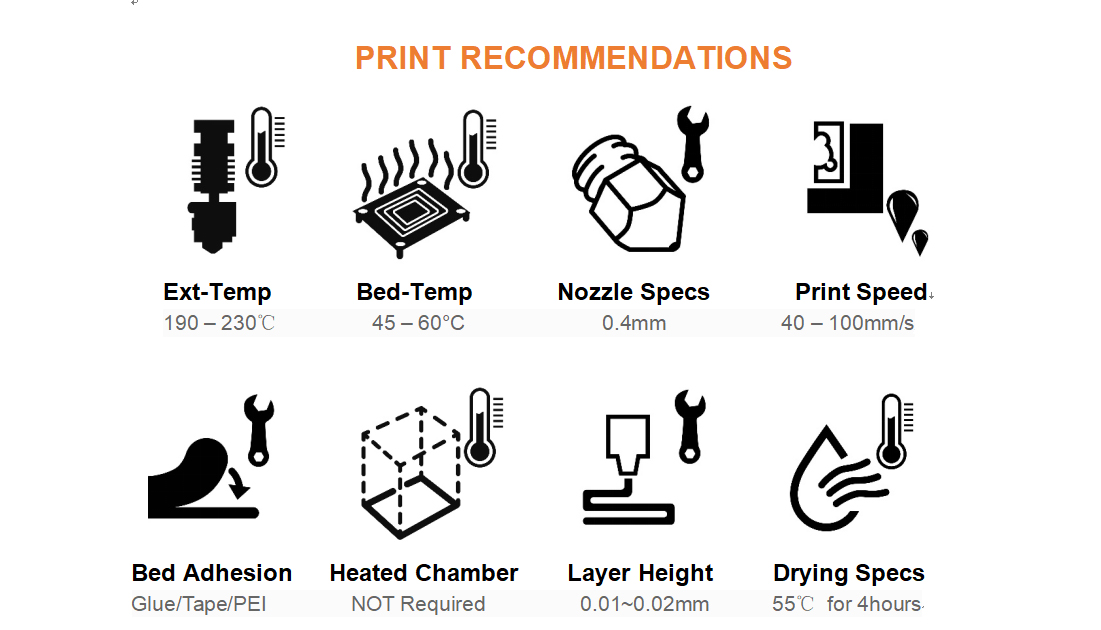

1. Yuav kom ua tiav qhov zoo tshaj plaws ntawm kev luam ntawv nrog cov xim sib txawv ntawm cov xim PLA filament, nws raug pom zoo kom siv lub nozzle txoj kab uas hla ntawm 0.4 hli lossis me dua. Cov nozzle txoj kab uas hla me dua tuaj yeem ua tiav cov ntsiab lus zoo dua thiab qhov zoo ntawm qhov chaw. Qhov kub ntawm kev luam ntawv pom zoo yog ntawm 200-220 ° C, nrog rau qhov kub ntawm txaj pw ntawm 45-65 ° C. Qhov ceev ntawm kev luam ntawv zoo tshaj plaws yog nyob ib puag ncig 50-60 hli / s, thiab qhov siab ntawm txheej yuav tsum nyob nruab nrab ntawm 0.1-0.2 hli.

2. Nco ntsoov kho qhov kawg ntawm cov xov paj tom qab txhua zaus siv, xws li ntxig qhov kawg ntawm cov xov paj rau hauv qhov kom tsis txhob muaj cov xov paj sib xyaw rau kev siv tom ntej.

3. Yuav kom txuas lub neej ntawm koj cov filament, thov khaws cia rau hauv lub hnab qhuav, kaw lossis lub thawv.

| Kub ntawm Extruder (℃) | 190 – 230℃Pom zoo 215℃ |

| Kub ntawm txaj (℃) | 45 – 65°C |

| NoQhov Loj | 0.4 hli |

| Kev Ceev Ntawm Lub Cua | Nyob rau ntawm 100% |

| Kev Ceev Luam Ntawv | 40 – 100 hli/s |

| Txaj pw sov | Xaiv tau |

| Cov Nto Ua Vaj Tse Pom Zoo | Iav nrog kua nplaum, Daim ntawv nplaum, Daim kab xev xiav, BuilTak, PEI |

Cov Lus Qhia Txog Kev Luam Ntawv:

1) Yuav kom ua tiav qhov zoo tshaj plaws ntawm kev luam ntawv nrog cov xim sib txawv ntawm cov xim PLA filament, nws raug pom zoo kom siv lub nozzle txoj kab uas hla ntawm 0.4 hli lossis me dua. Cov nozzle txoj kab uas hla me dua tuaj yeem ua tiav cov ntsiab lus zoo dua thiab qhov zoo ntawm qhov chaw. Qhov kub ntawm kev luam ntawv pom zoo yog ntawm 200-220 ° C, nrog rau qhov kub ntawm txaj pw ntawm 45-65 ° C. Qhov ceev ntawm kev luam ntawv zoo tshaj plaws yog nyob ib puag ncig 50-60 hli / s, thiab qhov siab ntawm txheej yuav tsum nyob nruab nrab ntawm 0.1-0.2 hli.

2) Nco ntsoov kho qhov kawg ntawm cov xov paj tom qab txhua zaus siv, xws li ntxig qhov kawg ntawm cov xov paj rau hauv qhov kom tsis txhob muaj cov xov paj sib xyaw rau kev siv tom ntej.

3) Yuav kom txuas lub neej ntawm koj cov filament, thov khaws cia rau hauv lub hnab qhuav, kaw lossis lub thawv.