PETG Carbon Fiber 3D Tshuab Luam Ntawv Filament, 1.75mm 800g/spool

Cov yam ntxwv ntawm cov khoom

| Brand | Torwell |

| Khoom siv | 20% Cov Khoom Siv Carbon Modulus Siab sib xyaw nrog80%PETG |

| Txoj kab uas hla | 1.75mm/2.85mm/3.0mm |

| Qhov hnyav tag nrho | 800g/lub voj; 250g/lub voj; 500g/lub voj; 1kg/lub voj; |

| Qhov hnyav tag nrho | 1.0Kg/spool |

| Kev kam rau siab | ± 0.03 hli |

| Lntev | 1.75 hli(800g) =260m |

| Chaw Khaws Khoom | Qhuav thiab cua nkag tau |

| Qhov Chaw Ziab Khaub Ncaws | 60˚C rau 6 teev |

| Cov ntaub ntawv txhawb nqa | Thov nrogTorwell HIPS, Torwell PVA |

| Kev Pom Zoo Txog Daim Ntawv Pov Thawj | CE, MSDS, Reach, FDA, TUV thiab SGS |

| Sib xws nrog | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker thiab lwm yam FDM 3D printers |

| Pob khoom | 1kg/lub raj; 8 lub raj/ctn los yog 10 lub raj/ctn lub hnab yas kaw nrog cov desiccants |

Ntau Xim

Kev Kos Duab Qhia

Pob khoom

| Qhov Ceev | 1.3 g/cm33 |

| Cov Ntsuas Kev Nqus Qhuav (g / 10 feeb) | 5.5(190℃/2.16kg) |

| Kub Distortion Temp | 85℃, 0.45MPa |

| Lub zog tensile | 52.5 MPa |

| Kev ntev thaum tawg | 5% |

| Lub zog flexural | 45MPa |

| Flexural Modulus | 1250MPa |

| Lub zog cuam tshuam IZOD | 8kJ/㎡ |

| Kev ruaj khov | 6/10 |

| Kev luam tawm tau | 9/10 |

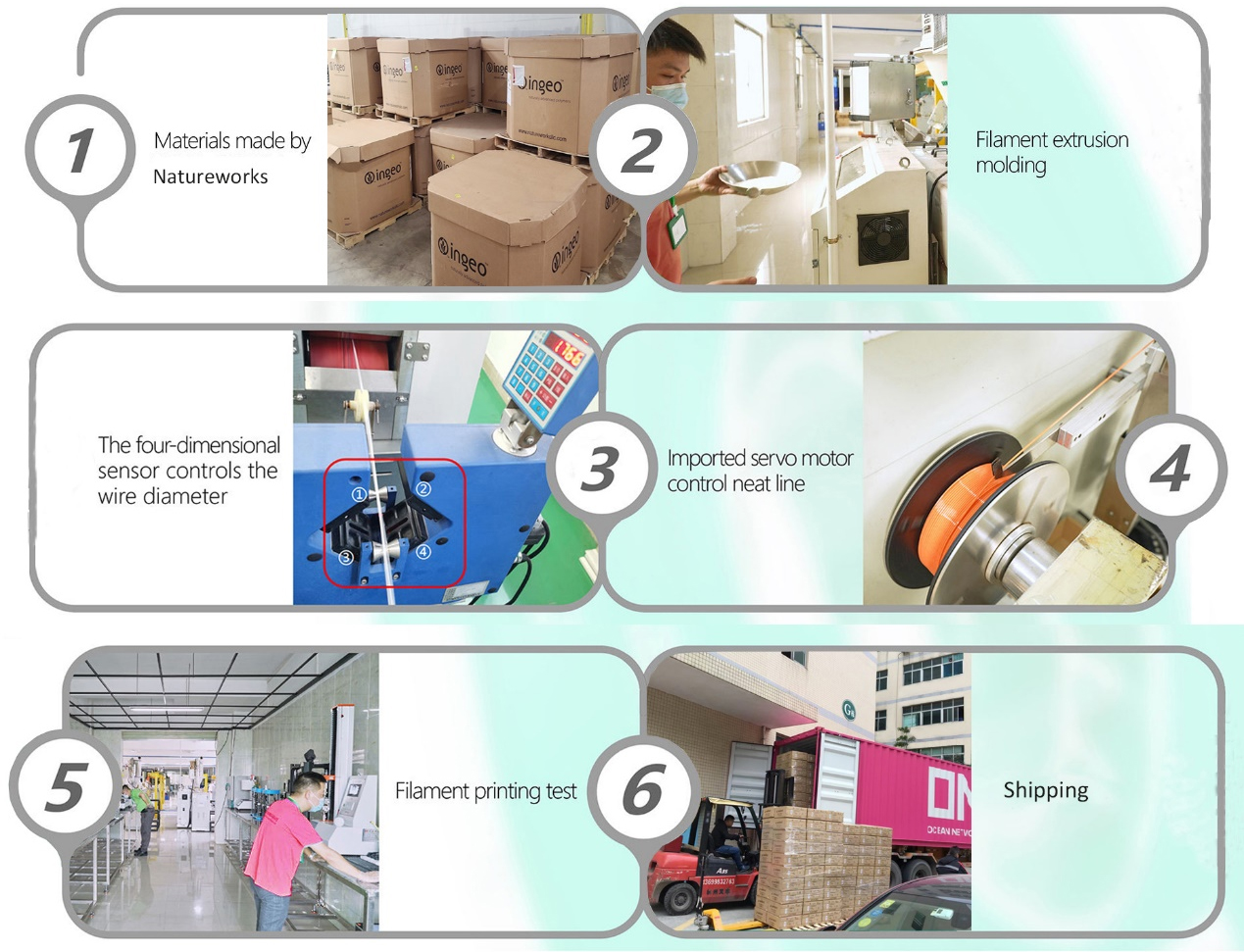

Chaw Ua Haujlwm Hoobkas

Torwell, ib lub chaw tsim khoom zoo heev nrog ntau tshaj 10 xyoo kev paub txog 3D luam ntawv filament.

Vim li cas PETG Carbon Fiber filament thiaj li nrov?

Carbon Fiber PETG 3D luam ntawv filament muaj lub zog siab heev rau qhov hnyav piv, siab tawv thiab rigidity, tsis kam rau kev puas tsuaj thiab hnav thiab tsim kua muag, tshuaj lom neeg zoo tiv taus dilute aqueous cov kua qaub, cov hauv paus, ntsev, thiab xab npum, nrog rau aliphatic hydrocarbons, cawv, thiab ntau yam roj.

Nws Yog Dab Tsi?

Cov fibers dav 5-10 micrometers ua los ntawm carbon. Cov fibers raug teeb tsa raws li lub axis ntawm cov khoom siv. Qhov no, nrog rau lawv cov qauv lub cev, yog qhov ua rau cov khoom siv no nws cov yam ntxwv zoo heev.

Nws Ua Dab Tsi?

Cov roj carbon fiber ntau ua rau pom ntau yam khoom zoo:

• siab tawv

• lub zog tensile siab

• ua siab ntev rau cua sov

• tiv taus tshuaj lom neeg siab

• qhov hnyav tsawg

kev nthuav dav thermal qis

Nws Ua Haujlwm Li Cas?

Kev siv cov roj carbon fiber los txhawb cov yas ua rau muaj cov filament luam ntawv 3D uas qhia txog cov khoom zoo tshaj plaws ntawm cov roj carbon fiber thiab cov yas uas koj xaiv.

Nws Zoo Rau Dab Tsi?

Zoo tagnrho rau txhua daim ntawv thov uas xav tau lub teeb yuag thiab rigidity. Vim li no, carbon fiber reinforced filament yog nrov heev hauv aerospace, civil engineering, tub rog, thiab motorsports.

Cov Khoom Siv Abrasive

Cov khoom siv no muaj zog heev ntawm cov filaments luam ntawv 3D. Cov neeg siv yuav pom tias cov nozzles tooj dag txheem raug zom sai heev piv rau cov qauv hnav thiab tsim kua muag. Thaum hnav dhau, lub nozzle txoj kab uas hla yuav dav dua tsis sib xws thiab lub tshuab luam ntawv yuav ntsib teeb meem extrusion.

Vim li no, nws raug pom zoo kom siv cov khoom siv no los luam tawm los ntawm lub qhov hlau uas tawv dua li cov hlau mos dua. Cov qhov hlau uas tawv feem ntau pheej yig thiab yooj yim rau kev teeb tsa nyob ntawm cov lus qhia ntawm koj lub tuam txhab luam ntawv.

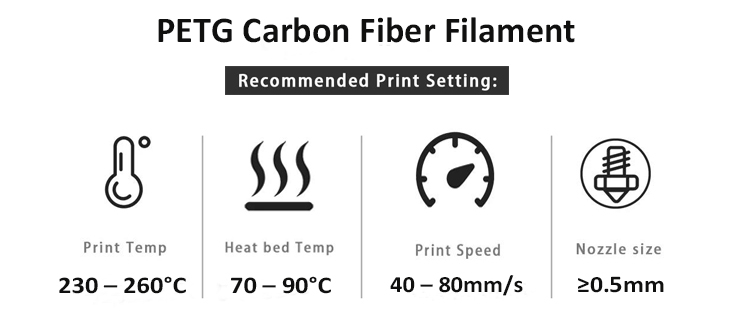

| Kub ntawm Extruder (℃) | 230 – 260℃Pom zoo 245℃ |

| Kub ntawm txaj (℃) | 70 – 90°C |

| NoQhov Loj | ≥0.5 hliNws zoo dua los siv Hardened Steel Nozzles. |

| Kev Ceev Ntawm Lub Cua | Nyob rau ntawm 100% |

| Kev Ceev Luam Ntawv | 40 –80hli/s |

| Txaj pw sov | Xaiv tau |

| Cov Nto Ua Vaj Tse Pom Zoo | Iav nrog kua nplaum, Daim ntawv nplaum, Daim kab xev xiav, BuilTak, PEI |